Understanding the Importance of Proper Duct Sizing

As a home construction specialist with over two decades of experience, I’ve seen my fair share of kitchen renovations. One aspect that’s often overlooked, yet crucial for a well-functioning kitchen, is the sizing of air ducts for range hoods. Let me tell you, getting this right can make a world of difference in your cooking space.

Proper duct sizing is not just about following building codes; it’s about creating an efficient, comfortable, and safe kitchen environment. I remember a project where a client insisted on using undersized ducts to save space. The result? A noisy range hood that struggled to clear the air, leaving lingering cooking odours throughout the house. It’s situations like these that underscore why we need to pay attention to the details.

The size of your kitchen air ducts directly impacts the performance of your range hood. Think of it like this: if you’re trying to breathe through a straw, you’ll struggle to get enough air. The same principle applies to your kitchen ventilation system. Undersized ducts restrict airflow, forcing the fan to work harder and less efficiently. On the flip side, oversized ducts can reduce air velocity, potentially allowing grease and odours to linger in the ductwork.

Factors Influencing Duct Size Selection

When I’m planning a kitchen renovation, several factors come into play when determining the right duct size. It’s not a one-size-fits-all solution, and that’s where my expertise comes in handy.

First and foremost, we need to consider the CFM (Cubic Feet per Minute) rating of the range hood. This measurement tells us how much air the fan can move. As a rule of thumb, here’s what I typically recommend:

| CFM Rating | Minimum Duct Size | Recommended Duct Size |

|---|---|---|

| 0-400 CFM | 4 inches | 6 inches |

| 401-600 CFM | 6 inches | 8 inches |

| 601-900 CFM | 7 inches | 8-10 inches |

| 901+ CFM | 8 inches | 10-12 inches |

But it’s not just about the CFM. The length of the duct run and the number of elbows or turns also play a significant role. Each bend in the ductwork adds resistance, reducing the overall efficiency. I always aim to keep the duct run as short and straight as possible. When that’s not feasible, I compensate by increasing the duct size or opting for a more powerful fan.

Another crucial factor is the cooking habits of the homeowner. Do they frequently use high-heat methods like stir-frying or indoor grilling? These activities generate more smoke and grease, requiring more robust ventilation. In such cases, I might recommend going up a size in ductwork to ensure optimal performance.

Common Mistakes in Kitchen Duct Installation

Over the years, I’ve seen my fair share of duct installation blunders. Let me share some of the most common mistakes I’ve encountered, so you can avoid them in your own projects.

One frequent error is using flexible ducts for range hood ventilation. While these might seem convenient, they’re not suitable for kitchen exhaust systems. The ridged interior of flexible ducts traps grease and reduces airflow efficiency. I always opt for smooth, rigid ducts for kitchen ventilation. They’re easier to clean and maintain, and they provide better airflow.

Another mistake I often see is improper sealing of duct joints. Leaky ducts can lead to reduced efficiency, increased energy costs, and even moisture problems in your walls or attic. I make it a point to use high-quality duct sealant or metal tape on all joints and connections. It’s a small step that makes a big difference in the long run.

Venting into attics or crawl spaces is another no-no that I’ve unfortunately encountered. This practice can lead to moisture buildup, mould growth, and even structural damage over time. Always ensure that your kitchen exhaust is vented directly to the outside of your home.

Optimizing Duct Layout for Maximum Efficiency

When it comes to duct layout, I always strive for the most efficient path possible. The ideal setup is a straight, vertical run from the range hood to the roof. However, we don’t always have that luxury in real-world situations.

If you need to run the duct horizontally, I recommend keeping it as short as possible and incorporating a slight upward slope. This helps prevent grease from accumulating in the ductwork. For every foot of horizontal run, I try to include at least a quarter-inch rise.

Minimizing the number of elbows is crucial for maintaining airflow efficiency. Each 90-degree turn in your ductwork can reduce the effective airflow by up to 50%. When turns are unavoidable, I opt for two 45-degree elbows instead of one 90-degree elbow. This smoother transition helps maintain better airflow.

In situations where a long duct run is necessary, I might recommend a more powerful fan to compensate for the increased resistance. It’s all about finding the right balance between duct size, fan power, and layout to achieve optimal performance.

Material Considerations for Kitchen Ducts

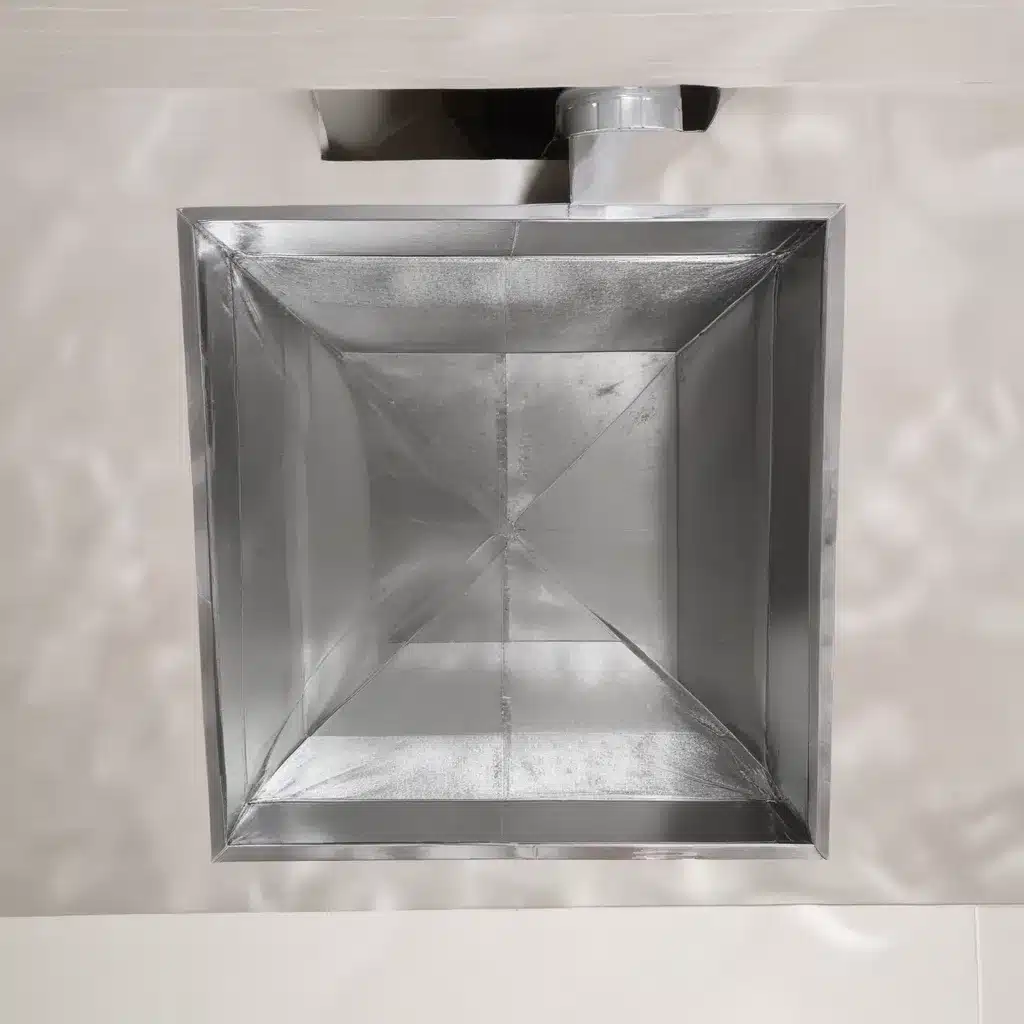

The choice of duct material can significantly impact the performance and longevity of your kitchen ventilation system. In my experience, galvanized steel and stainless steel are the top choices for kitchen ducts.

Galvanized steel is durable, fire-resistant, and relatively affordable. It’s suitable for most residential applications and can withstand the high temperatures associated with cooking. However, in coastal areas or other corrosive environments, I lean towards stainless steel for its superior corrosion resistance.

Aluminum is another option, particularly for shorter duct runs. It’s lightweight and easy to work with, but it’s not as durable as steel and may not be suitable for high-temperature applications.

Whatever material you choose, ensure it meets local building codes and fire safety standards. I always recommend checking with your local building department or consulting a professional to ensure compliance.

The Impact of Duct Size on Range Hood Performance

Let’s talk about how duct size directly affects your range hood’s performance. I’ve seen countless cases where a high-end range hood underperforms simply because it’s connected to undersized ductwork.

When the duct is too small, it creates back pressure, forcing the fan to work harder. This not only reduces the hood’s efficiency but also increases noise levels and energy consumption. It’s like trying to blow through a pinched straw – you’ll expend a lot of effort for little result.

On the other hand, oversized ducts can lead to a drop in air velocity. This might allow grease and other contaminants to settle in the ductwork, increasing the risk of clogs and potentially creating a fire hazard.

The key is to match the duct size to the hood’s CFM rating and the specific requirements of your kitchen. A properly sized duct allows the range hood to operate at peak efficiency, effectively removing smoke, odours, and grease from your cooking area.

Addressing Unique Challenges in Kitchen Ventilation

Every kitchen renovation brings its own set of challenges, and ventilation is no exception. I’ve encountered some tricky situations over the years, but with a bit of creativity and technical know-how, there’s usually a solution.

One common challenge is dealing with long duct runs in older homes or multi-story buildings. In these cases, I might recommend a remote blower system. By placing the fan unit closer to the exhaust point, we can maintain better airflow over longer distances.

Island cooktops present another unique challenge. Without a wall or ceiling directly above, we need to get creative with ductwork. I’ve used custom-built soffits or even incorporated ductwork into decorative ceiling features to address this issue.

In homes with tight spaces or structural limitations, we sometimes need to get innovative. I’ve used slim-profile ducts or even considered reconfiguring the kitchen layout to accommodate proper ventilation. It’s all about finding the right balance between functionality and aesthetics.

Maintenance Tips for Optimal Duct Performance

Proper maintenance is crucial for ensuring the longevity and efficiency of your kitchen ventilation system. Here are some tips I always share with my clients:

-

Regular Cleaning: Clean or replace your range hood filters every 1-3 months, depending on your cooking habits. This prevents grease buildup and maintains optimal airflow.

-

Annual Inspections: Have your ductwork professionally inspected at least once a year. This can help identify any issues like leaks, clogs, or damage before they become major problems.

-

Duct Cleaning: Consider professional duct cleaning every 2-3 years, or more frequently if you do a lot of high-heat cooking. This removes accumulated grease and debris, improving efficiency and reducing fire risks.

-

Check Exterior Vents: Regularly inspect your exterior vent covers to ensure they’re clean and functioning properly. Remove any debris or obstructions that might impede airflow.

-

Listen for Changes: Pay attention to any changes in your range hood’s performance or noise level. These could be signs of duct issues that need attention.

By following these maintenance practices, you can ensure your kitchen ventilation system continues to perform efficiently for years to come.

Future Trends in Kitchen Ventilation Technology

As someone who’s been in the industry for decades, I’ve seen significant advancements in kitchen ventilation technology. The future looks exciting, with innovations aimed at improving efficiency, reducing noise, and enhancing user experience.

Smart ventilation systems are becoming increasingly popular. These systems can automatically adjust fan speed based on cooking activities, temperature, and air quality. Some even integrate with smart home systems, allowing you to control your range hood via voice commands or smartphone apps.

Energy efficiency is another area of focus. We’re seeing the development of more efficient fan motors and aerodynamic duct designs that maximize airflow while minimizing energy consumption. This not only reduces operating costs but also lessens environmental impact.

Noise reduction technologies are also advancing. New range hoods are incorporating sound-dampening materials and improved fan designs to operate more quietly, even at high CFM levels.

As we look to the future, I expect to see continued innovation in materials and designs that make kitchen ventilation systems more effective, efficient, and user-friendly.

Conclusion: The Key to a Well-Ventilated Kitchen

In my years of experience, I’ve come to appreciate the critical role that proper duct sizing plays in creating a well-ventilated, comfortable kitchen. It’s not just about removing cooking odours; it’s about maintaining air quality, preventing grease buildup, and ensuring the safety and comfort of your home.

Remember, the best ventilation system is one that’s tailored to your specific needs and kitchen layout. Whether you’re planning a new kitchen or upgrading an existing one, don’t overlook the importance of proper duct sizing and installation.

If you’re embarking on a kitchen renovation journey and need expert guidance on ventilation or any other aspect of kitchen fitting, I highly recommend checking out the services offered by ABC Home. Their team of professionals can help ensure your kitchen not only looks great but functions perfectly too.

By paying attention to the details of your kitchen ventilation system, you’re investing in the long-term comfort, safety, and enjoyment of your home. After all, a well-ventilated kitchen is the heart of a happy home.