Understanding the Fundamentals of Kitchen Cabinet Construction

As a home construction specialist with years of experience under my belt, I’ve come to appreciate the intricacies involved in building kitchen unit bases. The foundation of any great kitchen lies in its cabinetry, and the base units are quite literally the backbone of this system.

When I first started in this field, I underestimated the complexity of cabinet construction. However, I quickly learned that a well-built base unit can make or break the functionality and longevity of a kitchen. It’s not just about slapping together some wood and calling it a day; there’s a science to it.

One of the most critical aspects of building kitchen unit bases is selecting the right materials. In my experience, 3/4-inch plywood is the gold standard for cabinet construction. It offers the perfect balance of strength, stability, and cost-effectiveness. I’ve tried using particle board in the past, but I found that it simply doesn’t hold up as well over time, especially in humid environments like kitchens.

The Art of Designing Your Cabinet Layout

Before you even think about cutting your first piece of wood, you need to have a solid plan in place. I can’t tell you how many times I’ve seen DIY enthusiasts jump into a project without proper planning, only to realize halfway through that their measurements are off or they’ve forgotten to account for appliances.

When I’m designing a kitchen layout, I always start by measuring the entire space meticulously. And I don’t just measure once – I measure three times to ensure accuracy. Remember, walls aren’t always perfectly straight, and floors aren’t always level. These small discrepancies can cause big headaches down the line if not accounted for in your initial design.

One tool I’ve found invaluable in the planning process is 3D modeling software. While it’s not strictly necessary, being able to visualize your kitchen in three dimensions can help you spot potential issues before they become real-world problems. Plus, it’s a great way to experiment with different layouts without lifting a finger.

Cutting and Preparing Your Materials

Once you have your design finalized, it’s time to start cutting your materials. This is where precision is key. I always tell my apprentices: “Measure twice, cut once.” It’s an old adage, but it holds true, especially in cabinet construction.

For cutting large sheets of plywood, I prefer using a track saw. It provides clean, straight cuts and is much safer than trying to maneuver a full sheet through a table saw. However, if you don’t have access to a track saw, a circular saw with a straight edge guide can work just as well.

When cutting your pieces, don’t forget to account for the thickness of your saw blade. It might seem insignificant, but over multiple cuts, those fractions of an inch can add up and throw off your entire project.

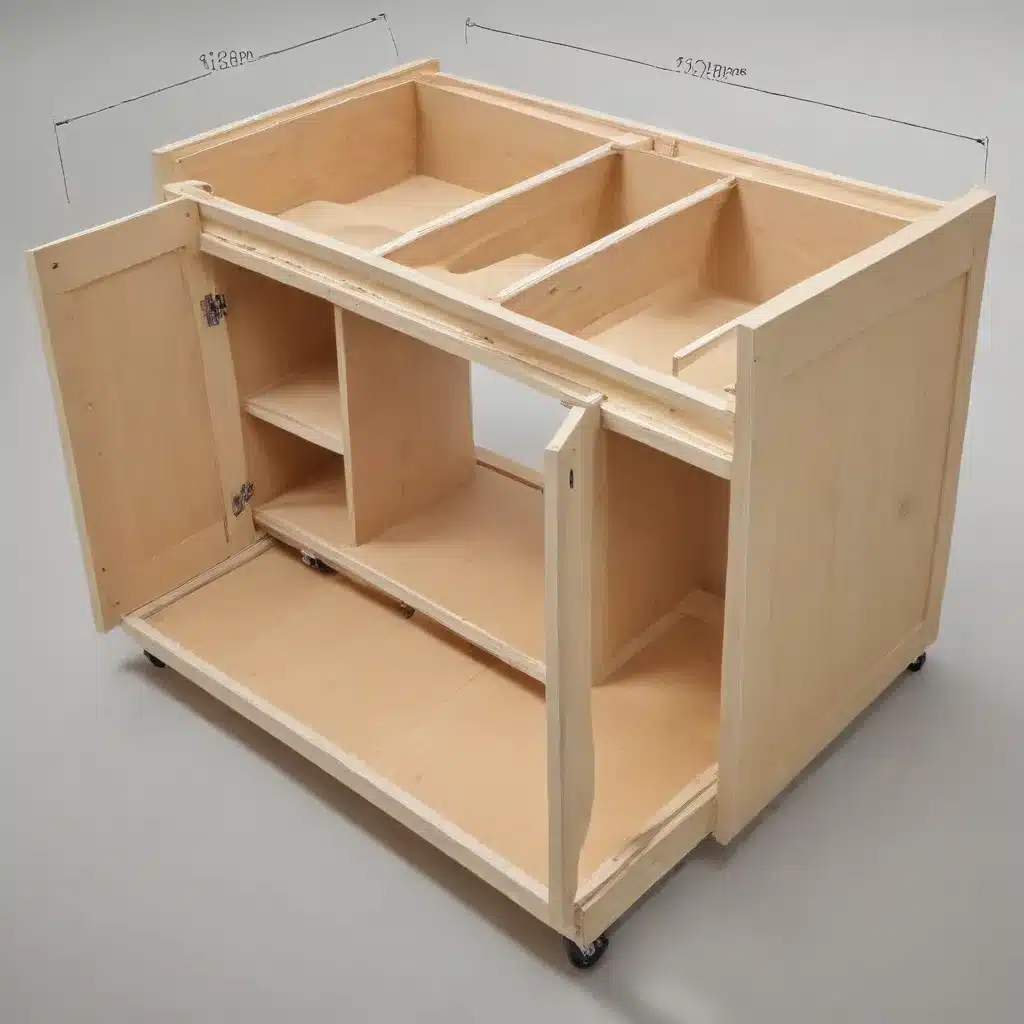

Assembling the Cabinet Base: A Step-by-Step Approach

Now that we have all our pieces cut, it’s time for assembly. This is where the real fun begins! Let’s break it down into manageable steps:

-

Start with the sides: Begin by attaching the bottom panel to the two side panels. I like to use pocket hole joinery for this as it creates a strong, hidden joint.

-

Add the back support: Next, attach a support strip along the back edge. This will provide additional strength and give you something to screw into when it comes time to mount the cabinet to the wall.

-

Install the face frame: If you’re using a face frame design (which I recommend for added strength and a more finished look), now’s the time to attach it. Make sure it’s flush with the edges of your cabinet box.

-

Add the toe kick: The toe kick not only gives your cabinet a finished look but also provides some much-needed foot space when standing at the counter. I typically set mine back about 3 inches and make it about 4 inches high.

Remember, throughout this process, it’s crucial to check for square. An out-of-square cabinet will cause all sorts of problems down the line, from doors that don’t close properly to countertops that don’t sit flat.

The Importance of Proper Hardware Installation

One aspect of cabinet construction that often gets overlooked is hardware installation. It might seem simple, but proper hardware can make a world of difference in both the functionality and longevity of your cabinets.

When it comes to hinges, I always opt for soft-close European-style hinges. They might be a bit more expensive upfront, but the added convenience and reduced wear and tear on your cabinet doors make them well worth the investment.

For drawer slides, full-extension ball-bearing slides are my go-to choice. They allow for full access to the drawer contents and can handle much more weight than cheaper roller slides.

Finishing Touches: Making Your Cabinets Shine

The final step in creating your perfect kitchen unit base is finishing. This is where you can really let your personal style shine through. Whether you prefer a natural wood look or a painted finish, the key is proper preparation.

If you’re going for a natural wood finish, I recommend using a pre-stain wood conditioner to ensure even absorption of the stain. For painted finishes, don’t skimp on the primer. A good primer will help your paint adhere better and provide a smoother final finish.

Remember, patience is key when it comes to finishing. Allow adequate drying time between coats, and don’t rush the process. A well-executed finish can elevate even the most basic cabinet design.

Safety Considerations in Cabinet Construction

As with any construction project, safety should always be your top priority when building kitchen unit bases. Here are a few key safety tips I’ve learned over the years:

-

Always use proper personal protective equipment: This includes safety glasses, hearing protection, and a dust mask.

-

Keep your work area clean: A cluttered workspace is a dangerous workspace. Clean up as you go to prevent tripping hazards.

-

Use tools properly: Each tool has a specific purpose. Using a tool incorrectly not only produces poor results but can also be dangerous.

-

Be aware of sharp edges: Freshly cut plywood can be surprisingly sharp. Handle with care to avoid cuts.

-

Lift safely: Kitchen cabinets can be heavy. Use proper lifting techniques or get help when needed.

By following these safety guidelines, you can ensure that your cabinet building experience is not only productive but also safe.

Innovations in Kitchen Cabinet Design

The world of kitchen cabinet design is constantly evolving, and as a construction specialist, it’s crucial to stay on top of the latest trends and innovations. One trend I’ve been particularly excited about is the integration of technology into cabinetry.

For example, I recently worked on a project where we installed LED lighting strips inside the cabinets. These were connected to sensors that automatically turned on the lights when the cabinet doors were opened. It’s a small touch, but it adds a whole new level of functionality and wow-factor to the kitchen.

Another innovation I’ve been incorporating into my designs is built-in charging stations. With so many of us relying on our devices in the kitchen – whether for recipes or just staying connected – having a dedicated space to charge phones and tablets has become increasingly important.

Sustainable Practices in Cabinet Construction

In recent years, I’ve noticed a growing demand for sustainable building practices, and cabinet construction is no exception. As a result, I’ve been exploring ways to make my cabinet building process more environmentally friendly.

One approach I’ve found effective is using formaldehyde-free plywood. Traditional plywood often contains formaldehyde-based adhesives, which can off-gas harmful chemicals into your home. Formaldehyde-free options provide the same strength and durability without the potential health risks.

I’ve also been experimenting with water-based finishes instead of traditional oil-based ones. These finishes have come a long way in recent years and now offer comparable durability with much lower VOC emissions.

Common Mistakes to Avoid in Kitchen Cabinet Construction

Over the years, I’ve seen (and admittedly, made) my fair share of mistakes when it comes to building kitchen unit bases. Here are a few common pitfalls to watch out for:

-

Overlooking the importance of leveling: An unlevel cabinet might not seem like a big deal, but it can cause issues with drawer function and even lead to countertop problems down the line.

-

Forgetting about utilities: Always plan for plumbing and electrical needs before building your cabinets. It’s much easier to accommodate these elements during construction than to try and retrofit later.

-

Skimping on support: Don’t underestimate the weight of countertops, especially if you’re using stone. Make sure your cabinet bases are sturdy enough to support the weight.

-

Ignoring wood movement: Wood expands and contracts with changes in humidity. Failing to account for this can lead to warped doors and drawers that stick.

-

Rushing the finish: A beautiful finish takes time. Rushing through the sanding and finishing process will only lead to disappointing results.

By being aware of these common mistakes, you can avoid them in your own projects and achieve professional-quality results.

The Role of Technology in Modern Cabinet Design

As technology continues to advance, its influence on cabinet design and construction is becoming increasingly apparent. One area where I’ve seen significant progress is in the realm of 3D printing. While still in its early stages for full-scale cabinet production, 3D printing is already being used to create unique hardware and decorative elements.

Another technological advancement that’s changing the game is CNC (Computer Numerical Control) machining. These machines allow for incredibly precise cuts and joinery, resulting in cabinets that fit together perfectly every time. While CNC machines were once only accessible to large manufacturers, smaller, more affordable models are now available for small shops and serious DIYers.

The Future of Kitchen Cabinet Design

Looking ahead, I see some exciting developments on the horizon for kitchen cabinet design. One trend I’m particularly interested in is the move towards more modular, adaptable cabinet systems. As our living spaces become more flexible, our kitchens need to keep up.

I’m also seeing a growing interest in smart cabinets. These might include features like built-in inventory systems that can track what you have in stock and even place orders automatically when you’re running low on staples.

Regardless of what the future holds, one thing remains constant: the need for quality construction. No matter how advanced our technology becomes, there’s no substitute for well-built, properly installed cabinets.

Conclusion: The Art and Science of Kitchen Cabinet Construction

Building kitchen unit bases is truly a blend of art and science. It requires technical skill, an eye for design, and a deep understanding of materials and construction techniques. Whether you’re a seasoned professional or a DIY enthusiast, I hope this guide has provided you with valuable insights into the world of cabinet construction.

Remember, every kitchen is unique, and what works in one space might not be ideal for another. Don’t be afraid to experiment and find solutions that work best for your specific needs. And if you ever find yourself in over your head, don’t hesitate to reach out to a professional. At ABC Home, we’re always happy to lend our expertise to help you create the kitchen of your dreams.

Building kitchen cabinets may seem daunting at first, but with patience, practice, and attention to detail, you can create beautiful, functional cabinets that will stand the test of time. Happy building!